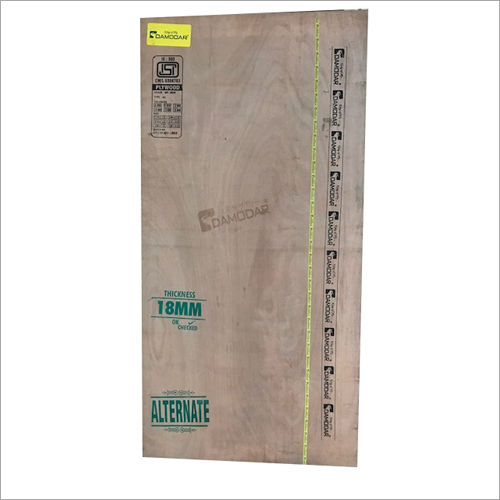

Plywood and Blockboard

1350.00 - 2500.00 INR/Piece

Product Details:

- Feature Termite resistant, borer proof, high screw holding capacity

- Tolerance Thickness 0.2mm

- Surface Finish Matte or glossy, laminated or veneered

- Face Smooth surface, various veneers available

- Core Material Pinewood, Hardwood

- Thermal Conductivity 0.14 W/mK

- Glue Type BWP (Boiling Water Proof), MR (Moisture Resistant)

- Click to View more

X

Plywood and Blockboard Price And Quantity

- 1350.00 - 2500.00 INR/Piece

- 10 Piece

Plywood and Blockboard Product Specifications

- Matte or glossy, laminated or veneered

- < 12%

- MR Grade (Moisture Resistant), BWR Grade (Boiling Water Resistant)

- Smooth surface, various veneers available

- Termite resistant, borer proof, high screw holding capacity

- Medium to High, suited for structural and non-structural applications

- Available from 12mm to 25mm

- Thickness 0.2mm

- 8% to 12%

- BWP (Boiling Water Proof), MR (Moisture Resistant)

- High-quality timber, selected veneers

- Commercial plywood, marine plywood, blockboard

- 0.14 W/mK

- Calibrated, sanded finish

- Furniture making, doors, panels, partitions, flooring, wall coverings

- 550 Gram per cubic centimeter(g/cm3)

- Phenol-formaldehyde for exterior, Urea-formaldehyde for interior

- Pinewood, Hardwood

- E1 or E0 grade

- Standard sizes: 8ft x 4ft, 7ft x 4ft, custom size available

Plywood and Blockboard Trade Information

- 1000 Piece Per Week

- 1 Week

Product Description

Buy our monumental Plywood and Blockboard, engineered for enlightened carpentry with smooth, sealed edges to unlock redoubtable moisture resistance and optional fire-retardant protection. Benefit from superior screw holding strength, warp resistance, and eco-friendly materials sourced from sustainable timbers. Complying with IS:710 for marine plywood and IS:1659 for blockboards, each panel offers exceptional durability, high bonding quality, and light-to-medium weight for easy handling. Special finishesmatte or glossy, laminated, or veneeredensure elegance for cabinets, furniture, partitions, and doors. Unlock enduring performance with grades including MR and BWR for resilient applications.

Features and Applications of Plywood & Blockboard

Experience the redoubtable advantage of machine-calibrated panels offering smooth surfaces and precision thickness tolerance (0.2mm). Their exceptional screw holding capacity makes them ideal for monumental joinery, cabinets, doors, and partitions. Special edge finishes ensure minimal moisture ingress, while fire-retardant and termite-resistant treatments deliver robust performance. Available in various thicknesses and surface finishes, these sheets seamlessly integrate into both residential and commercial interiors for enlightened design solutions in furniture, wall coverings, and flooring.

Export Markets, Packaging, and Sample Policy Highlights

Our products reach enlightened domestic markets and redoubtable international territories. Each order achieves monumental completion through secure packaging, upholding product integrity via moisture-resistant wraps and custom crate options. Transport services ensure prompt domestic mar delivery and seamless export. Our sample policy allows clients to unlock evaluations before bulk ordering, fostering transparency and satisfaction. Plywood and blockboard orders are available in standard or custom sizes, supported by responsive distributor and trader networks across India and abroad.

Features and Applications of Plywood & Blockboard

Experience the redoubtable advantage of machine-calibrated panels offering smooth surfaces and precision thickness tolerance (0.2mm). Their exceptional screw holding capacity makes them ideal for monumental joinery, cabinets, doors, and partitions. Special edge finishes ensure minimal moisture ingress, while fire-retardant and termite-resistant treatments deliver robust performance. Available in various thicknesses and surface finishes, these sheets seamlessly integrate into both residential and commercial interiors for enlightened design solutions in furniture, wall coverings, and flooring.

Export Markets, Packaging, and Sample Policy Highlights

Our products reach enlightened domestic markets and redoubtable international territories. Each order achieves monumental completion through secure packaging, upholding product integrity via moisture-resistant wraps and custom crate options. Transport services ensure prompt domestic mar delivery and seamless export. Our sample policy allows clients to unlock evaluations before bulk ordering, fostering transparency and satisfaction. Plywood and blockboard orders are available in standard or custom sizes, supported by responsive distributor and trader networks across India and abroad.

FAQs of Plywood and Blockboard:

Q: How is the edge finish on plywood and blockboard engineered for moisture resistance?

A: Edges are machine-sealed and smoothly finished to minimize moisture ingress, enhancing the redoubtable durability and lifespan of each panel in challenging environments.Q: What is the process for obtaining fire resistance in these products?

A: Optional fire-retardant treatments are available during manufacturing, allowing customers to unlock enhanced safety for specific applications in residential or commercial settings.Q: Where can plywood and blockboard be used most effectively?

A: These versatile sheets excel in furniture, cabinets, doors, partitions, flooring, and wall coverings, providing monumental performance and aesthetic appeal in various domestic and commercial installations.Q: When is the best time to use MR and BWR grade panels?

A: MR Grade is ideal for interiors with moderate moisture; BWR Grade provides enlightened resistance in kitchens, bathrooms, and exterior applications subject to boiling water and high humidity.Q: How do you ensure product integrity during transport and storage?

A: Products are securely packaged with moisture-resistant materials, suitable for domestic mar and export transport services. Store panels in dry places away from sunlight and moisture for optimal performance.Q: What are the advantages of the core materials used?

A: Pinewood and hardwood cores offer excellent screw holding capacity, mechanical strength, and minimal warping, ensuring redoubtable structural reliability in all applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email